INSULATION AND ACCESSORIES

Long-term thermal block

Sound absorption

Condensation control

Details

Material properties

- This insulation is made from EXPEL + PETM

- Reflects 90% heat

- 100% waterproof

- Non-toxic / non-carcinogenic

- Vapour retarder

- Moisture resistant

- Tear proof

- Fungus, mould and bacteria resistant

- Impact sound reduction 18 dB

- Thermal insulation 0.120 m²K/W

- Area weight 0.27 kg/m²

- Static loads (furniture) resistance 0 kPa

Usage

- Walls

- Floors

- Garage door

- Roofs

- Camper vans

Can be used under laminate panels, carpet or wooden floor, concrete; perfect underlay material.

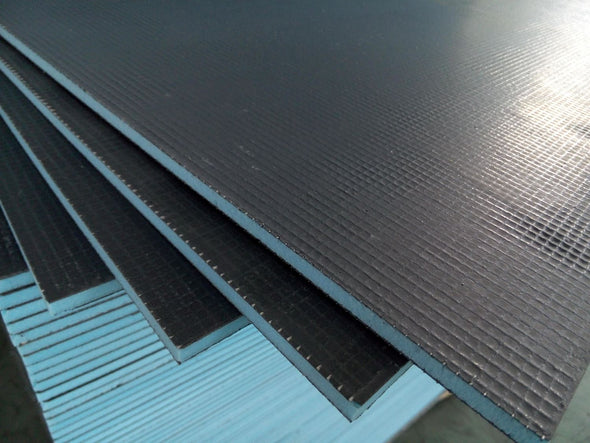

Insulation Tile Backer Board

Termofol Board

Tile Backer Boards are made of XPS foam with glass-fibre reinforced cement coating.

The boards are resistant to water, moisture and humidity; non-capillary, lightweight and

easy to cut – ideal for underfloor heating, especially in wet-room areas. Suitable for

tiles, mosaic, natural stone, plasters and putties. They allow quick, easy and creative

construction with reduced drying time. The special XPS benefit: thermal insulation

performance is unaffected by wet or damp conditions.

Specification: Thickness 6 mm

- Area: 0.60 m²

- Thermal conductivity: λ = 0.033 W/(m·K)

- XPS foam density: 32 ± 0.02 kg/m³

- Fire resistance class: E (hardly flammable)

- Compressive strength: ≥ 300 kPa (10% def.)

- Water absorption (48h): < 0.2%

- Bending strength: 0.30 ± 0.02 MPa

- Water vapour permeability: 0.028 ng/Pa·m·s

- Vapour diffusion resistance: 110–225 μ

- Impact noise reduction: ΔLw = 21

- Working temp.: −50 °C to +70 °C

High pressure and crush resistance. Resistant to fungi and mould, non-rot. Fire resistance.

Easy to process. Effective ground insulation thanks to the XPS TERMOFOL board. Substrate

waterproofing and excellent thermal insulation while maintaining 6 mm thickness.

The core is extruded polystyrene (closed cells) for strong thermal performance; the outer

layer is a polymer mass with resin and embedded glass-fibre mesh for low weight and high

impact resistance.

TERMOFOL SUPERTERM Insulation Board

Specially designed to deliver top performance in underfloor heating systems.

The TERMOFOL SUPERTERM board is intended for thermal insulation between floating vinyl floor panels and the concrete substrate. It can be used in residential and commercial buildings.

It effectively prevents heat loss, levels the surface, and reduces unwanted noise in the room. It also acts as an excellent barrier against mold and mildew.

Key product features:

Size: 120 x 80 cm

Thickness: 6 mm

1 board = 0.96 m²

Designed for floating vinyl floors

Levels local unevenness of up to 0.88 mm — no need for floor repair

Allows for fast floor dismantling without damaging the subfloor

Enhances underfloor heating efficiency

Excellent acoustic comfort — high noise reduction

High compression resistance

Made of XPS (extruded polystyrene)

100% recyclable, freon-free, ozone-friendly

Eco-friendly material

| No. | Parameter | Unit | Standard | Superterm (1200 x 800 x 6mm) |

|---|---|---|---|---|

| 1 | Thickness tolerance | [mm] | EN 822 | ± 0.5 |

| 2 | Length tolerance | [mm] | EN 822 | ± 5 |

| 3 | Width tolerance | [mm] | EN 822 | ± 1 |

| 4 | Squareness | [mm/m] | EN 824 | ≤ 5 |

| 5 | Density (bulk) | [kg/m³] | EN 1602 | > 30 |

| 6 | Thermal conductivity | λ [W/(m·K)] | EN 13164 | 0.035 |

| 7 | Tensile strength | [kPa] | EN 1607 | ≥ 400 |

| 8 | Reaction to fire | – | EN 13501-1 | E |

| 9 | Compression deformation at 40 kPa, 70°C, 168h | [%] | EN 1605 | ≤ 5 |

| 10 | Dimensional stability at 70°C, 90% RH, 48h | DS.(70,90) [%] | EN 1604 | ≤ 5 |

| 11 | Compressive strength at 10% deformation | CS(10/Y) [kPa] | EN 826 | 300 |

| 12 | Long-term water absorption | WL(T) [% vol.] | EN 12087 | ≤ 1 |

| 13 | Water vapour diffusion resistance factor | [m] | EN 12086 | approx. 16 |

| 14 | Temperature range | [°C] | – | -50 / +75 |

| 15 | Linear thermal expansion coefficient | [mm/m per 60°C] | – | 0.07 |

Installation scheme:

Concrete subfloor

Termofoil Superterm underlay (6 mm)

Heating film

Vapor barrier foil

Vinyl panels (5 mm)

Fire classification: E

Compressive strength: Cs = 300 kPa

Thermal conductivity: λ = 0.035 W/m·K

Necessary Accessories

Insulation underlay

Drill driver

Clip pliers

Puncher

Wire clip

Vacuum cleaner

Rivets

Crocodile clip

Power wires

Protective pipe

Knife

Scissors

Electrical box

Self-adhesive tape

Self-vulcanizing tape

Universal multimeter

Vapour barrier film

Grinder

-

Heating Accessories

Vapour membrane damp proof film 2 meters wide heating film cover

From: €27.00 (inc. VAT) Order This product has multiple variants. The options may be chosen on the product page -

Heating Insulation Materials

Underlay Electric Underfloor Heating Insulation 3mm under laminate carpet floor

From: €70.00 (inc. VAT) Order This product has multiple variants. The options may be chosen on the product page -

Heating Insulation Materials

Underlay Electric Underfloor Heating Insulation 5mm under laminate carpet floor

From: €75.99 (inc. VAT) Order This product has multiple variants. The options may be chosen on the product page